SDG

9

Industry, Innovation

and Infrastructure

Improving resource efficiency has numerous benefits both for industry and society. It not only reduces our dependence on the world’s limited resources, but it also helps to reduce waste and ensure that we can achieve more with less. In the metal packaging industry, increased resource efficiency is achieved through a combination of innovative product development, inventive policy ideas and new technologies.

LED lighting covers 75% of shop floors, with the objective to reach 100% by the end of 2024. This transition will reduce electricity demand for lighting by 90%. 100% of UK plants are already supplied with renewable electricity.

Use of heat generated during the can-manufacturing process to heat the entire building since 2019.

The heat is also transformed into cool water, which is used to cool production machines and the administration building as needed.

Targeting the use of

100 %

renewable energy by 2030

Reduction in weight of 33cl cans by

This innovation has now been extended to 44cl and 50cl cans, with the potential to save 3.3 million hectolitres of water and cut CO2 emissions by 28,000 tonnes.

7 %

across the majority of production facilities.

This innovation has now been extended to 44cl and 50cl cans, with the potential to save 3.3 million hectolitres of water and cut CO2 emissions by 28,000 tonnes.

The plan is to take further actions that will lead to the reduction in CO2 emissions by a further

10 %

in 2021.

Kettering greenfield plant became the largest aluminium beverage can plant in the United Kingdom when it opened in February 2023. It also became a model for future greenfield plants.

The plant includes heat capture from RTO systems

for offices on site, a solar water heating system for

the domestic water supply, a rainwater recovery system

that feeds into toilet facilities, automatic on/off on all plant LED lighting

and 20 electric car chargers for employees.

for offices on site, a solar water heating system for

the domestic water supply, a rainwater recovery system

that feeds into toilet facilities, automatic on/off on all plant LED lighting

and 20 electric car chargers for employees.

2025 targets to reduce electricity consumption by

7 %

and thermal energy consumption by 6% energy. At a global level, 7.8% of our current electricity is powered by renewable energy.

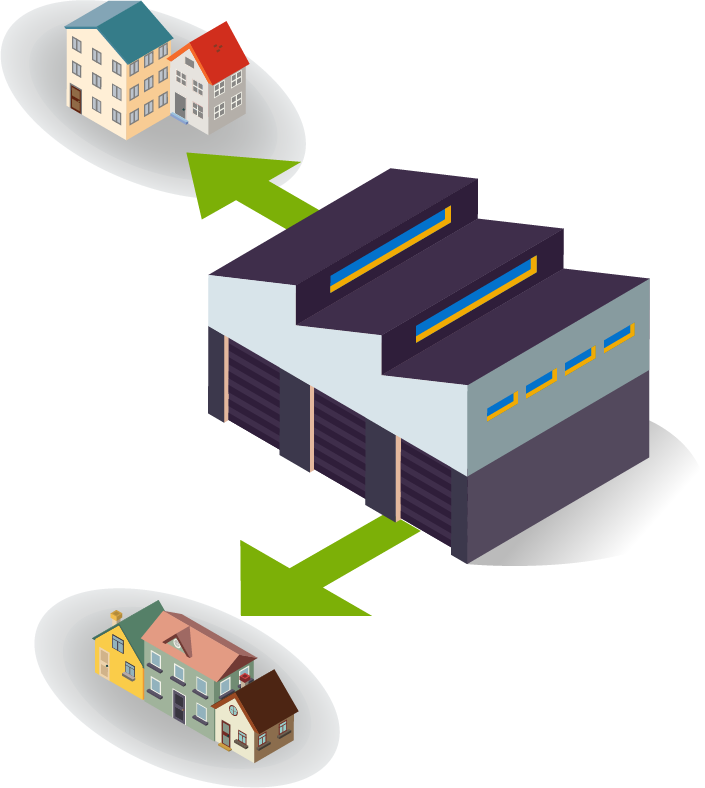

Heat exchanger installed in the aluminium can plant in Hämeenlinna, Finland,

has reduced the amount of energy needed to heat the building by about 30%.

has reduced the amount of energy needed to heat the building by about 30%.

A heat exchanger installed in 2022 captures clean, hot air from the Regenerative Thermal Oxidiser (RTO) in the French Moëlan-sur-Mer plant and reuses it for lacquering processes. The project has achieved an estimated energy reduction of 500MWh per year.

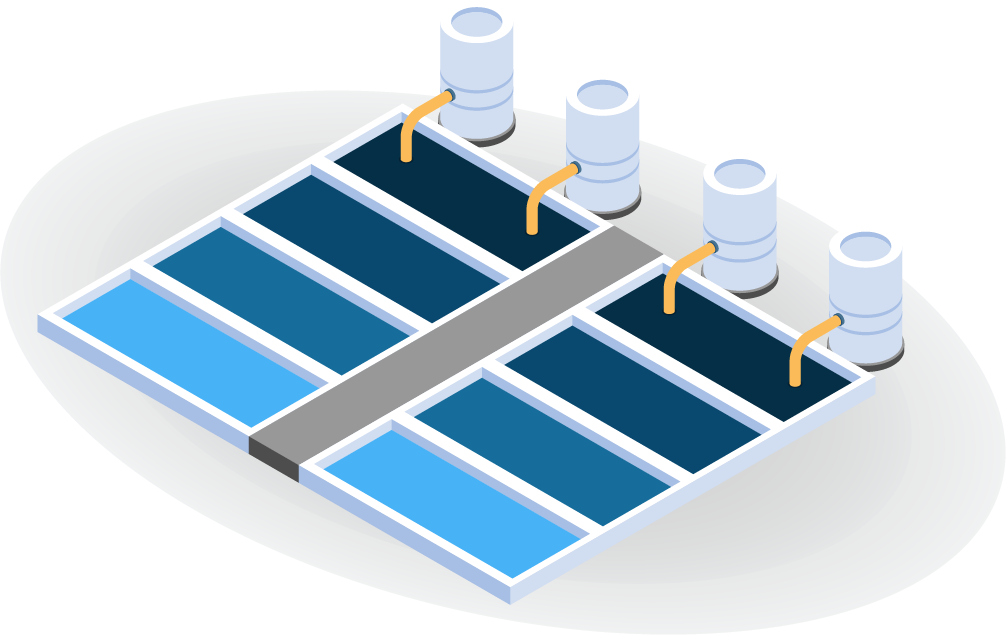

A new plant in Heerenveen, designed with sustainability as a priority, became operational in 2022. The plant uses geothermal heating, sensor lighting and green electricity. Excess warmth during the summer period is stored deep underground and can later be transferred to the plant in the winter.